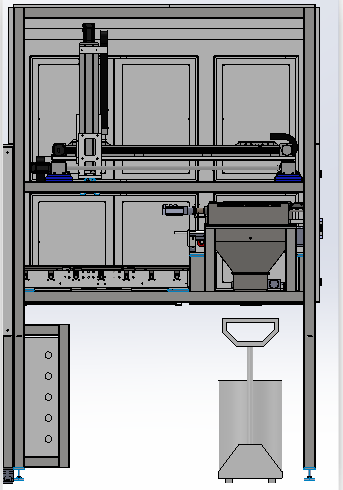

Intelligent Loading & Unloading System of Push Rod Furnace

Intelligent Loading & Unloading System of Push Rod Furnace

As a full-automatic assembly line, the push rod furnace intelligent loading & unloading system is to reduce the complex oxide powders at setted temperature with hydrogen as the reductant. The system comprises the main parts: boat hooking mechanism, unloading mechanism, boat cleaning mechanism, descaling mechanism ,weighing mechanism, shaking mechanism,boat starting mechanism and boat pushing mechanism.

The system adopts the Modularization Design based on PC control,making every unit of work (uow) is not only an independent workstation but a tightly fitting system, and every uow cooperates closely to achieve the automatic loading & unloading production.

The system is equipped with self designed push rod furnace intelligent machine loading & unloading software, which adopts the Industrial PCs-based control technology from BECKOFF (Germany) company to improve the control speed and the positioning accuracy, by using EtherCAT distributed control network, adopting monitoring management software to transmit the on-site production situation in real time to realize modern production management.

Brief Introduction of the Main Function of Equipment

Automatic discharging mechanism (hooking boat unit) is XYZ three-axis manipulator , X-axis adopts servo motor plus pinion rack mechanism,Z-axis uses servo motor plus chain traction actuator,through our unique search and location technology to perform the corresponding furnace pipe positioning and compensating the position error caused by furnace pipe position fluctuation,Y-axis boat hooking mechanism uses servo motor plus chain driver to control the opening & closing of the furnace gate to hook out the boat .

Descaling Mechanism

The three layers of boat separation and transportation is operated by three-axis combined manipulator. In order to product the superfine powder, we adopt the three-layer protection and reversal mechanism with patented technology to makes the dust spillover to a very small amount, and the amplitude of inverting is very small. With the inertia gas protection chamber, we can ensure that spontaneous combustion will not occur during the production of the ultra-fine tungsten powder.

Boat Descaling Mechanism

After a period of time, the boat’s surface will appear a layer of powder scales. It will affect the reduction reaction of tungsten powder if the scales is not removed, it will affect the quality of tungsten powder, and it is not conducive to product classification. Our system has three groups of slag cleaning mechanisms that can be used to brush the upper, middle and lower boat separately. And this mechanism can regularly cleans boat and remove the scales according to the actual production demand without workers, which brings great convenience to the production and reduces the labor intensity of the workers.

Weighing Mechanism

The Distributing device includes three parts: storage cylinder, 3 groups of vibration controller and weighing platform. The storage cylinder can be customized according to the actual needs of customers (normal 100kg). In order to meet the precise weighing control, we adopt vibration feeding principle and use the three speed control system.

Shaking Mechanism

According to the eccentric wheel control theory, three groups of independent devices were designed for the shaking mechanism to perform the reciprocating movement of the boat with freely adjusted shaking speed & reciprocating times to meet the different requirements of production.

Boat Closing Mechanism

The boat closing mechanism adopts SMC electrical cylinder YZ module to perform the left right calibration of the boat and the folding of three layers of boat, it is also equipped with front and rear position calibration mechanism to ensure the proper operation of the boat stacking.

Boat Pushing Mechanism

The boat pushing mechanism is another kind of XYZ three-axis manipulator device, in which the X-axis adopts the servomotor plus gear rack mechanism, the Z axis adopts the servomotor plus chain mechanism, and the Y-axis adopts the servomotor plus chain driving. It controls the opening & closing of the furnace gate and push the boat into the furnace pipe.

Pumping Mechanism

The tungsten oxide raw materials is to be delivered to the storage bucket by the vacuum extraction system , and the material level of the storage bucket is controllable.

Transmission Mechanism

The transmission mechanism adopts step-by-step lifting mode, so that the boat can run smoothly with very low failure rate.

Safety performance

The material charging and discharging are operated through single pipe, which will avoid the simultaneous operation of multiple furnace pipe, reduce the consumption of hydrogen and keep the pressure of hydrogen on a stable level, ensure to operate the push rod furnace more safely.

Our equipment is equipped with UPS, in the event of a sudden power outage or other unforeseen failures, the whole equipment will stop safely with the front and rear furnace gates in the closing position. Even under the extreme conditions of the furnace charging-gate malfunction, the hook boat unit is equipped with a separate operator interface for the operator to close the furnace charging-gate manually, and it is also equipped with mechanical manual closing hardware device to ensure that the furnace gate can be closed under all conditions to minimize risk.

The boat hooking mechanism is equipped with a boat detection device to judge whether the boat has been successfully pulled out of the furnace pipe, and there is interlock function between the boat hooking mechanism and the boat pushing mechanism, which will avoid the simultaneous gates opening of a same furnace pipe on both hooking boat side and the pushing boat side, which will cause hydrogen leakage.

The safety of the equipment is reinforced with the automatic alarm on Over temperature, Timeout unprocessed, Insufficient hydrogen pressure,and the Safety pressure deflating explosion-proof functions

System Performance Parameter

| NO | ITEM | PARAMETER |

| 1 | makespan | 7.5min |

| 2 | weighing accuracy | <±5g |

| 3 | product protection | Yes |

| 4 | protective atmosphere(superfine powder production ) | Carbon dioxide or nitrogen |

| 5 | slag removal function | Yes |

| 6 | Line speed | >0.25m/s |

| 7 | (Positioning accuracy of boat hooking and boat pushing mechanism) | <±0.5mm |

| 8 | (Transverse walking speed of boat hooking and boat pushing mechanism) | >0.5m/s |

| 9 | Working force of boat-pushing mechanism at furnace head | >300kgf |

| 10 | Equipment system power supply and power | three phase 380V,P<30KW |

| 11 | Air supply | >0.6Mpa |

| 12 | Line size(mm) | 15750×1400 |

| 13 | boat hooking and boat pushing mechanism base size(mm) | 4680×600 |

The intelligent loading and unloading system products of push rod furnace developed by our company have been authorized with 10 patents. The main patents are as follows:

Invention Patent:The utility model relates to an intelligent loading and unloading system for a push-rod furnace

Software Copyright:

Pusher furnace intelligent machine Handling system software

Utility model: The utility model relates to an intelligent boat slag cleaning mechanism

Utility model: The utility model relates to an intelligent boat powder shaking mechanism

Utility model: The utility model relates to an intelligent pushing and hooking boat mechanism

Utility model: The utility model relates to a metal powder distributing mechanism